ROOF/Soffit

Designers looking to specify any roof and/or ceiling to meet or exceed NCC/BCA energy efficiency

requirements for buildings of any height.

Selecting the correct insulation type and thickness needs to be carried out in conjunction with the thermal

assessment either using the deem to satify or modeling.

We provide a guide to insulation types and thicknesses to allow the designer to control the space

required and the location to meet requirements such as condensation, waterproofing, thermal bridging,

airtightness, fire and acoustic performance. Final approval must be sort by the authority having

jurisdiction using test and engineering documentation provided by the manufacturer.

Car Park Soffit insulation can be found in Floor

Designers looking to specify any roof and/or ceiling to meet or exceed NCC/BCA energy efficiency

requirements for buildings of any height.

Specification

Manufacturer's documents distributed by Integra Building Products and De Silva Solutions, products are

made from imported and locally produced components.

- DeSilvaLine by Pirmax made in Australia

- Brownie by Ecowool

- DePolyLine XPS by Foamex Styroboard XPS made in Australia

- Fastwrap by Don & Low and Paul Industries (NZ) made in United Kingdom

- Fullers Toolbox made in Australia

- PPC foil tape made in Australia

- Brownie by Ecowool

- DePolyLine XPS by Foamex Styroboard XPS made in Australia

- Fastwrap by Don & Low and Paul Industries (NZ) made in United Kingdom

- Fullers Toolbox made in Australia

- PPC foil tape made in Australia

Sarking (Climate Zone 4-8), Vapour permeable pliable

building membrane laid over roof framing members, as required by AS 4200.2 to

manage condensation and rainwater leaks.20mm PIR Rigid board thermal break

insulation below framing members and batt type thermal and acoustic insulation

laid at the ceiling line.

- WARNING: Do not use reflective foil laminates if batt

insulation is installed at ceiling line.

Sarking (Climate Zone 1-3), Foil laminate vapour barrier

laid over roof framing members, as required by AS 4200.2 to manage condensation

and rainwater leaks.

Wire safety mesh: as required.

Metal roofs - pliable building membrane/sarking

Product: Fastwrap HW vapour permeable pliable building membrane.

Description: Fastwrap Flamespec HW Roof underlay is a synthetic building underlay for use under roog

claddings. The underlay consists of a micro-porous water resistant film laminated to two layers of non-

woven spun-bonded polyolefin. Fastwrap HW roof underlay is coloured grey with writing on the top face

and white on the bottom face.

Installation: Lay sarking vertically over battens, perpendicular to the gutters (do not use foil faced blanket

above the attic space for climate zone 4-8) Lay sarking with writing facing outwards for vapour

permeable building membranes, starting at one of the fascia boards and make sure 25 mm is draped into

the gutter to facilitate drainage. Lay the sarking sagged slightly between battens to keep it away from the

underside of the roof sheet, but no more than 40 mm or what is required to facilitate drainage. Locate the

sarking in position with staples and then install the roof sheet directly over the sarking. Tape overlaps

between adjoining runs of sarking to prevent spillage of any water captured due to condensation or rain if

the roof pitch is below 5 degrees.

Tile roofs - pliable building membrane/sarking

Product: Fastwrap HW vapour permeable pliable building membrane.

Description: Fastwrap Flamespec HW Roof underlay is a synthetic building underlay for use under roog

claddings. The underlay consists of a micro-porous water resistant film laminated to two layers of non-

woven spun-bonded polyolefin. Fastwrap HW roof underlay is coloured grey with writing on the top face

and white on the bottom face.

Installation: Lay sarking horizontally over rafters, parallel to the gutters (do not use reflective foil above

the attic space for climate zones 4-8 (writing to face outwards for vapour permeable building

membranes), commencing at the gutter line with 25 mm draped into the gutter to facilitate drainage.

Temporarily locate the sarking in position with a nail or screw prior to securing in place with the roof

battens. Cascade subsequent layers of sarking by overlapping by 150 mm to shed water to the gutter

and overlap the ridge by 150 mm each side.

Metal roofs – bulk insulation (when no insulation present at the ceiling line)

Product: Brownie by Ecowool

Description: Brownie Glasswool the formaldehyde free range of ECOWOOL-Brownie glass mineral

wool insulation manufactured by PGF Insulation employs formaldehyde free binder that is free of

formaldehyde, phenol or any other artificial chemicals.

Installation: As follows:

- Fascia and gutter: Trim roof blanket flush at the edge of the external side of fascia where the gutter’s back wall starts. Do not allow the blanket to drape into the gutter. This location is where the cladding will pinch the roof blanket down onto the fascia top edge and close off the corrugated profile openings.

- Ridges: Install an roof blanket from opposing sizes over ridge. Extend the roof blanket over the ridge and abut an existing roof blanket on the other side. Make sure the foil portion of the blanket extends 150 mm crossing over a support member. Peel 150 mm of bulk insulation from existing blanket and trim off. Flap foil end to end laps in a cascading manner whilst ensuring bulk insulation abuts.

- Tears and penetrations: Seal with a contact pressure sensitive adhesive tape (such as PPC 493 72 mm wide tape) applied using a “squeegee” applicator tool to the underside of the foil. Provide additional cleaning of the foil membrane surface if sealing the tape from above when access is limited from below.

- Hot flue penetrations: Provide 25 mm clearance between the roof blanket and any hot surface. Do not adhere tapes around a hot flue.

- Fascia and gutter: Trim roof blanket flush at the edge of the external side of fascia where the gutter’s back wall starts. Do not allow the blanket to drape into the gutter. This location is where the cladding will pinch the roof blanket down onto the fascia top edge and close off the corrugated profile openings.

- Ridges: Install an roof blanket from opposing sizes over ridge. Extend the roof blanket over the ridge and abut an existing roof blanket on the other side. Make sure the foil portion of the blanket extends 150 mm crossing over a support member. Peel 150 mm of bulk insulation from existing blanket and trim off. Flap foil end to end laps in a cascading manner whilst ensuring bulk insulation abuts.

- Tears and penetrations: Seal with a contact pressure sensitive adhesive tape (such as PPC 493 72 mm wide tape) applied using a “squeegee” applicator tool to the underside of the foil. Provide additional cleaning of the foil membrane surface if sealing the tape from above when access is limited from below.

- Hot flue penetrations: Provide 25 mm clearance between the roof blanket and any hot surface. Do not adhere tapes around a hot flue.

Waterproof membrane roofs – IRMA/PMR types

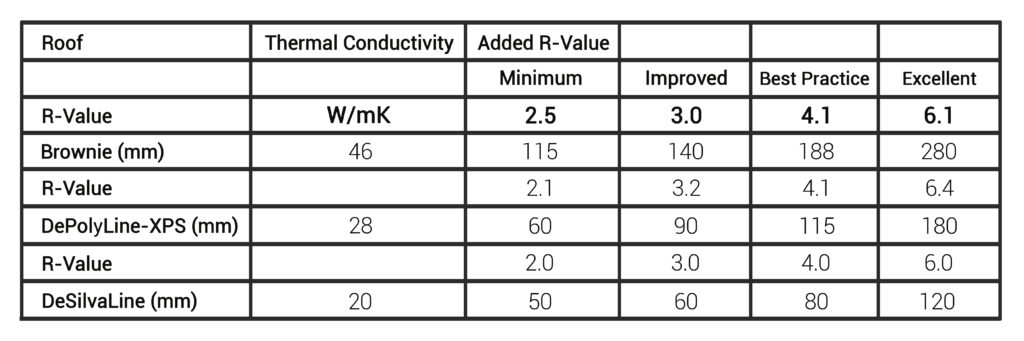

Product: DePolyLine XPS by Foamex /DeSilvaLine by Pirmax

Description: DePolyLine XPS is a extruded closed cell rigid insulation board which will resist water

uptake and has a compressive strength between 200-350 kPa. It is used as thermal insulation above or

below waterproof roof membrane systems.

Description: DeSilvaLine PIR is a modified polyurethane (PIR-polyisocyanurate) rigid foam board with

reflective pure foil facer either side of the PIR core. The product is suitable for use as thermal insulation

below roof membrane systems.

Preparation: Make sure membrane is clean and free of loose material.

Seperation Layer : Lay over membrane with edges lapped 300 mm and turned up at upstands and

penetrations.

Installation: Lay insulation boards in brick pattern with shiplap edges pushed together firmly, cut neatly

around penetrations and extend up upstands.

Finish: Stone ballast/pavers/sheet membrane/tile

Cathedral ceiling insulation – metal roofing and roofing tiles

Product: Fastwrap Vapour permeable membrane with Brownie bulk ceiling batts at ceiling line.

Membrane Installation: To AS 4200.2. Install the membrane with a sag sufficient to facilitate drainage

(but not more than 40 mm), 150 mm lapped joins between sheets and over the ridge, and 25 mm draped

over fascia board.

Bulk Isulation Installation: To AS 3999. Install the glass wool insulation batts between rafters avoiding

contact with the underside of the sarking.

Ceiling insulation – bulk insulation

Product: Brownie by Ecowool

Description: Brownie Glasswool the formaldehyde free range of ECOWOOL-Brownie glass mineral

wool insulation manufactured by PGF Insulation employs formaldehyde free binder that is free of

formaldehyde, phenol or any other artificial chemicals. the product is suitable for use as thermal

insulation fitted within a frame.

Framed and suspended ceilings: Fibre batts.

Application: Over ceiling lining.

Installation of Batts: Fit tightly between framing members.

Ceiling Vapour Barrier and Thermal Break- rigid board (Climate Zone 4-8)

Product: DeSilvaLine PIR [20/25mm]

Description: DeSilvaLine PIR is a modified polyurethane (PIR-polyisocyanurate) rigid foam board with

reflective pure foil facer either side of the PIR core. The product is suitable for use as an airtight layer

fitted below the framed and suspended ceiling.

WARNING: This product can not form any part of a fire resistant construction where an FRL is required

for the ceiling.